The evolution of the household refrigerator is not a well known story. There seems to be few people interested in the subject. Perhaps it is not as romantic as the development of the automobile. Nonetheless, a concerted effort was put forth in the 1920s and 1930s to produce a cheap, reliable, efficient domestic refrigerator. From books I’m reading on the subject, the great diversity of refrigerator manufacturers in the United States that existed in the 1920s, seems to be boiled down to a handful of companies in the depression era. In the most recent book, “Household Electric Refrigeration” by John F. Wostrel and John G. Praetz 1938; the models described were made by manufacturers, many still around today (or owned by yet larger companies) including General Electric, Frigidaire, Kelvinator, Norge, Grunow, Crosley, Sparton, Hotpoint, Coldspot, Copeland, Ice-O-Matic and Westinghouse.

One of the most noticeable differences between refrigerators in the mid 1930s and today was the refrigerants they used and the refrigerants charges required for operation. A very common refrigerant, Sulpher Dioxide had been in use fora number of years and still appeared to dominate the market at this time, not to say that proprietary chemical refrigerants weren’t beginning to take a large part of the market. F-12 was one of these proprietary substances that would later dominate the refrigerator industry. It was stable up to high temperatures, didn’t stink like SO2 when it leaked, was relatively safe if exposure to it was kept to a minimum, and it has a much lower boiling point than several common refrigerants at the time which means that systems operating F-12 remained in a positive pressure state throughout the cycle. Refrigerators with F-114, SO2, Isobutane and Methyl Formate required a vacuum in the low side of a vapor compression system. This was generally viewed as problematic seeing that if a leak formed in the low side of the system, for instance, around the packing seal of an open drive compressor, atmosphere would leak into the system, bringing non-condensable gases and water vapor. This leads to high head pressures, oil contamination, possible acid formation, corrosion and refrigerant control freeze ups. A curious refrigerant used rarely was Carrene, also known as Dichloromethane which has a boiling point of 104 degrees F at atmospheric pressure. This means both the suction and discharge sides of a system would operate in a vacuum state. Very curious. As I said, the refrigerant charges were unusual as well. The compressors of these systems were rated not much larger than modern day compressors from 1/16 HP up to 1/4 HP, but they had typical charges of 1# to perhaps 3.5# and more depending on the manufacturer. Modern refrigerators have charges measured in ounces, perhaps, 4 oz.. Most of these machines had liquid receivers that held excess refrigerant and ensured a pure liquid supply to the refrigerant control. That excess refrigerant would have allowed continued operation with minor leaks in the system. Another reason for the large charges is the construction of the evaporator which was commonly gravity flooded; a vessel and series of tubes holding refrigerant under low pressure, boiling away to vapor as heat is absorbed from the refrigerated cabinet.

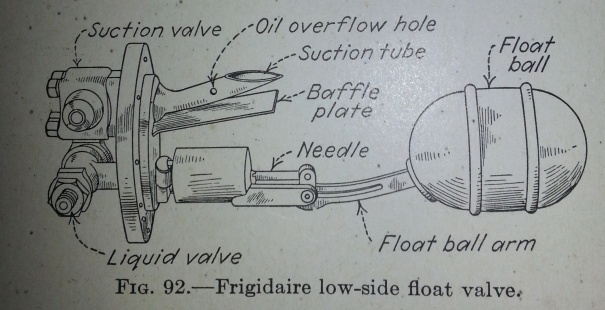

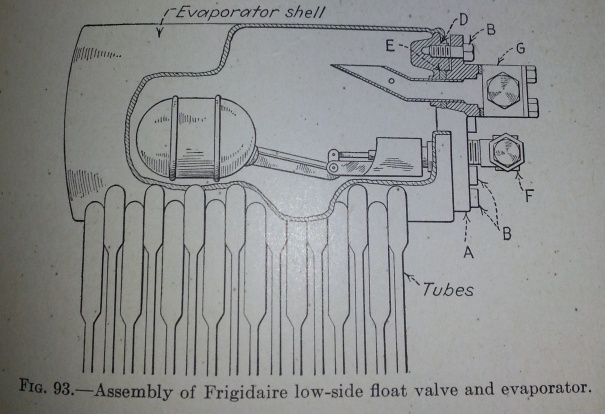

Above, is one of these low side float assemblies. These seemed to be falling out of favor by the mid 1930s for various reason having to do with expense and reliability. The float valve simply regulated the volume of liquid refrigerant within the evaporator shell which was maintained at suction pressure. As the refrigerant boiled away and was carried to the compressor, the ball would drop, valve open and additional high pressure liquid would be admitted. When implemented properly, the low side float gravity flooded evaporator has many advantages over the high side float or the dry type evaporator. It was very important that these machines were properly leveled when installed. They definitely had a minimum charge volume below which the float valve would continually call for more refrigerant and when it was not available, the valve would remain open, leaving very little pressure drop between the high and low side resulting in little to no refrigerating effect. A large refrigerant charge could simply be handled with a sufficiently sized liquid receiver. (Also read The Great Gravity Flooded Evaporator)

Nearly the same valve assembly, but removed from the evaporator housing. The baffle plate depicted helped to prevent the violent, boiling liquid refrigerant from being carried back the suction tube to the compressor. Some compressor oils would form a thin film on top of the refrigerant and would need carried back to the compressor. Various methods for this were devised; this Frigidaire obviously had a carefully placed hole in the suction tube for the purpose.

Nearly the same valve assembly, but removed from the evaporator housing. The baffle plate depicted helped to prevent the violent, boiling liquid refrigerant from being carried back the suction tube to the compressor. Some compressor oils would form a thin film on top of the refrigerant and would need carried back to the compressor. Various methods for this were devised; this Frigidaire obviously had a carefully placed hole in the suction tube for the purpose.

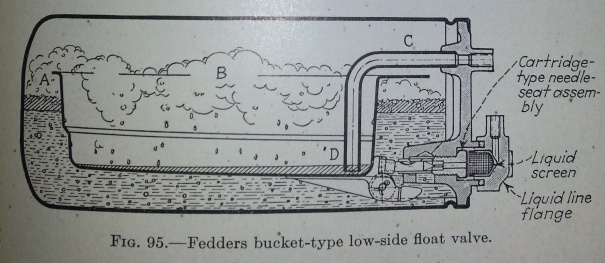

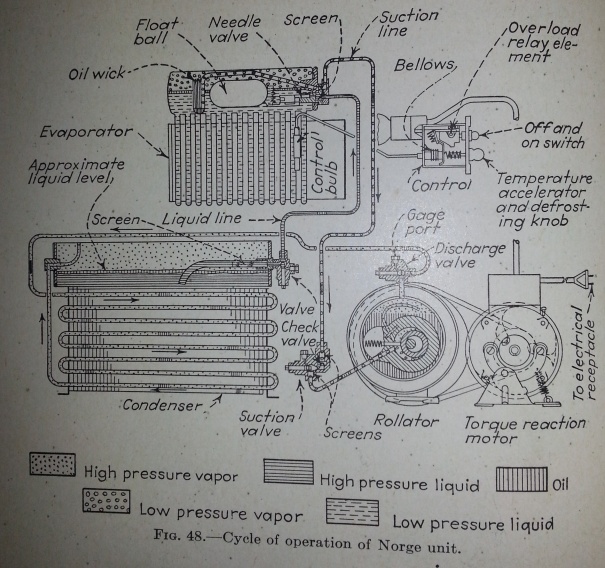

Another low side float valve assembly. It’s a beautiful illustration isn’t it? I read a patent on this type, and one of the advantages cited was that with an open, floating pan, the whole device is under equal pressure, there is no worry of it’s reliable operation, unlike a sealed ball float. The other use of the pan, as I think is well illustrated, is it’s use to collect oil vapors and collect them in the bottom for return to the compressor via the suction tube. I believe this float valve needle and valve seat can be removed and serviced without taking out the entire float assembly.

Another low side float valve assembly. It’s a beautiful illustration isn’t it? I read a patent on this type, and one of the advantages cited was that with an open, floating pan, the whole device is under equal pressure, there is no worry of it’s reliable operation, unlike a sealed ball float. The other use of the pan, as I think is well illustrated, is it’s use to collect oil vapors and collect them in the bottom for return to the compressor via the suction tube. I believe this float valve needle and valve seat can be removed and serviced without taking out the entire float assembly.

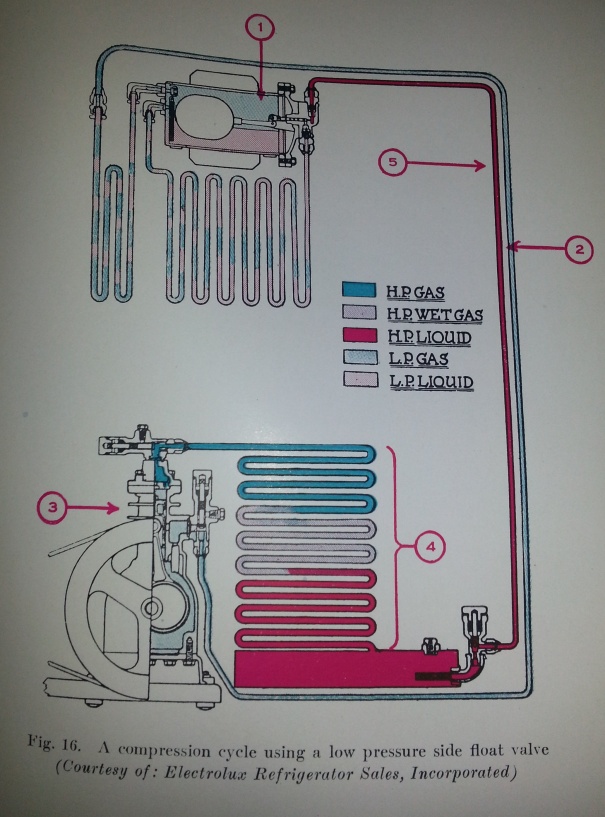

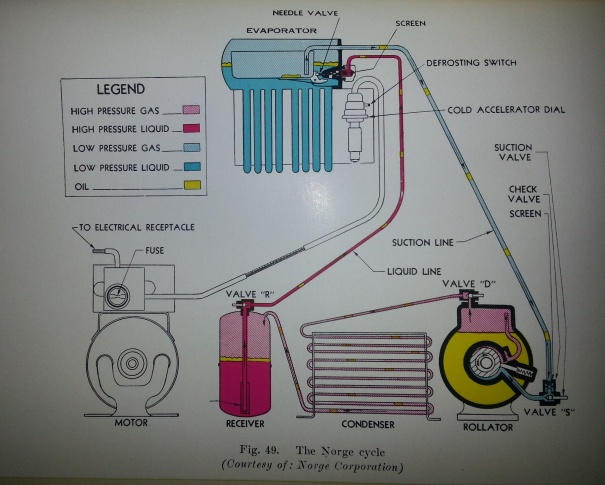

A color illustration from “Modern Electric and Gas Refrigeration” by Althouse and Turnquist, 1933. Notable features: Pan Type Low SIde Float, Open Drive Rotary Compressor.

From the same 1933 book, this Electrolux diagram has some neat features. It’s an open drive reciprocating compressor probably with a fan cooled condenser. Most domestic units were fan cooled by this time. Early in the 20s, the higher head pressures associated with atmospheric condensers made water cooled condensers more common. WIth the addition of condenser cooling fins and the increased air flow from fans tied to higher speed electric motors, air cooling became more practical. This unit has a curious evaporator. All though it has a low side float, the evaporator coil is one continuous loop like a dry type evaporator. This could lead to vapor pockets forming and elevated pressures over the suction pressure, decreasing the rate of ebullition. Another interesting feature being the extra loop or two in the suction line to vaporize any liquid refrigerant in the suction line.

From the same 1933 book, this Electrolux diagram has some neat features. It’s an open drive reciprocating compressor probably with a fan cooled condenser. Most domestic units were fan cooled by this time. Early in the 20s, the higher head pressures associated with atmospheric condensers made water cooled condensers more common. WIth the addition of condenser cooling fins and the increased air flow from fans tied to higher speed electric motors, air cooling became more practical. This unit has a curious evaporator. All though it has a low side float, the evaporator coil is one continuous loop like a dry type evaporator. This could lead to vapor pockets forming and elevated pressures over the suction pressure, decreasing the rate of ebullition. Another interesting feature being the extra loop or two in the suction line to vaporize any liquid refrigerant in the suction line.

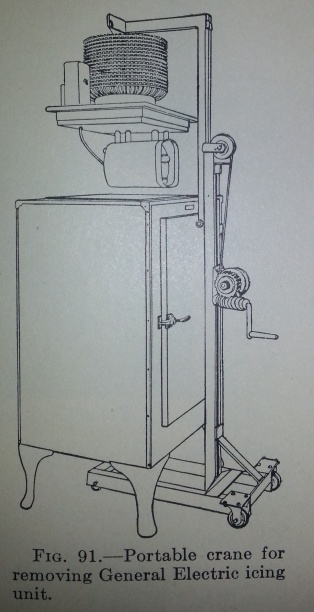

A common GE Monitor Top type refrigerator. This “package type” construction was common where the entire refrigerating apparatus was modular in that it could be easily removed from the cabinet for service or replacement.

A common GE Monitor Top type refrigerator. This “package type” construction was common where the entire refrigerating apparatus was modular in that it could be easily removed from the cabinet for service or replacement.

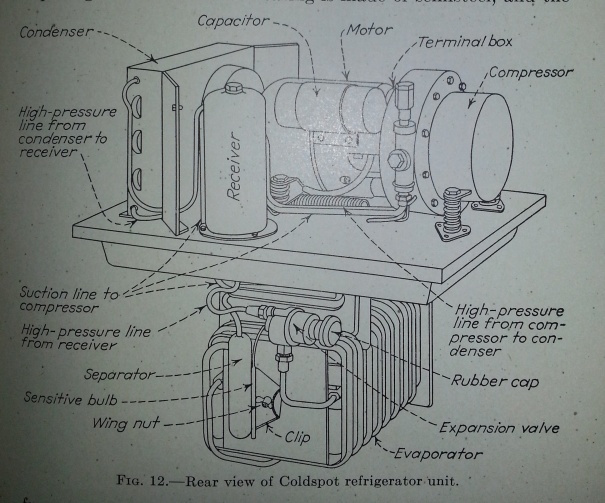

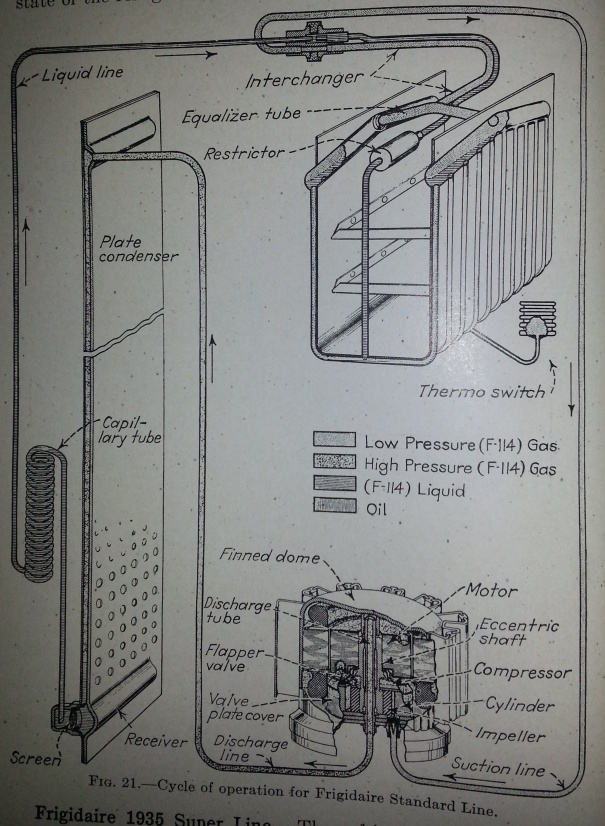

This Coldspot has some features worth discussing. For one, it is the package type as described before with the compressor and condensing unit mounted atop the insulated cabinet top with the motor and compressor supported my springs to dampen vibration and noise. The evaporator is of the dry type where the refrigerant is fed to a long coil of tube or series of tubes at approximately the rate in which it is vaporized by the heat of the refrigerated cabinet. Some of the more crude early versions of this used a fixed orifice called a “restrictor”, having a fixed, triangle shaped opening to pass high pressure liquid refrigerant to the evaporator. Before the capillary tube came into use (invented in the late 20s) was the Automatic Expansion Valve which is little more than a pressure regulating valve maintaing a constant pressure within the evaporator coil, often with an adjustable spring compression. This knob or screw would often go out of adjustment because of the constant freeze/thaw occurring at these valves. They were often equipped with a rubber cap or boot to keep moisture from interfering with the adjustment. These AXVs work well in constant load conditions, but under high load tend to starve the evaporator of refrigerant and risk slugging liquid back to the compressor under low load. The improvement to these valves came with the addition of a thermostatic element or “sensor bulb” strapped to the suction line, the temperature of which alters the pressure within the the bulb and in turn, operates a diaphragm inside the valve to properly feed the correct amount of refrigerant to the coil given the conditions. This type of valve would be called a Thermostatic Expansion Valve.

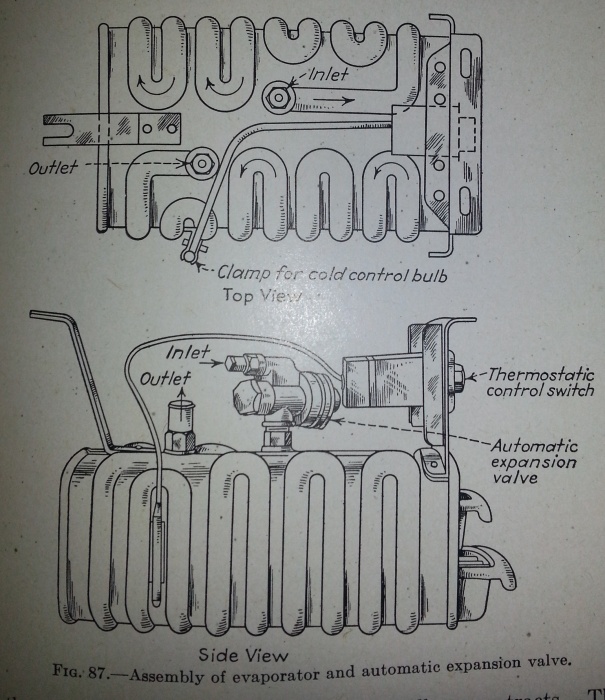

A very simple dry type evaporator with and AXV. Notice the Thermostatic Control Switch. This has nothing to do with the refrigerant supply, but simply controls the electrical current to the compressor and allows the operator to adjust the cabinet temperature. These worked with a thermostatic bulb strapped to the evaporator, suction line or somewhere else in the cabinet. The Thermostat was a great improvement over the controls of the 20s which sometimes used a pressure operated switch tied into the suction line. The service or replacement of these complicated switches could involved breaking the sealed refrigerant line.

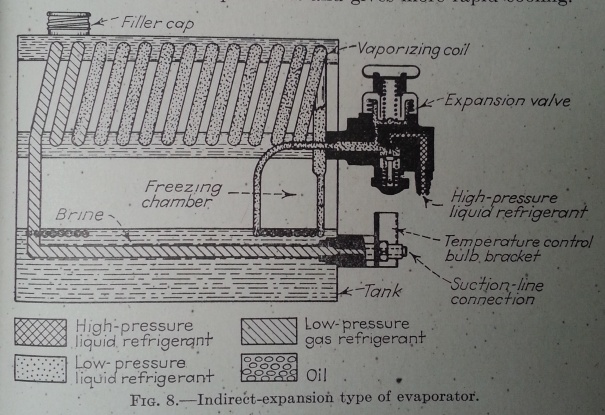

An AXV on a dry type coil, but rather than direct expansion, this is a brine tank. The refrigerant tube passes through of a low freezing point brine which in turn froze ice cubes and chilled the space. These had the advantage of having a holdover effect to keep the cabinet cold and prevent short cycling of the compressor and also had a more constant loading effect on the AXV which made for more consistent and predictable performance. The down side of a brine system is the possible corrosive effects of the brine, extra cabinet space taken and the lower evaporator temperatures possibly needed to chill the brine to a temperature that it could in turn chill the refrigerator.

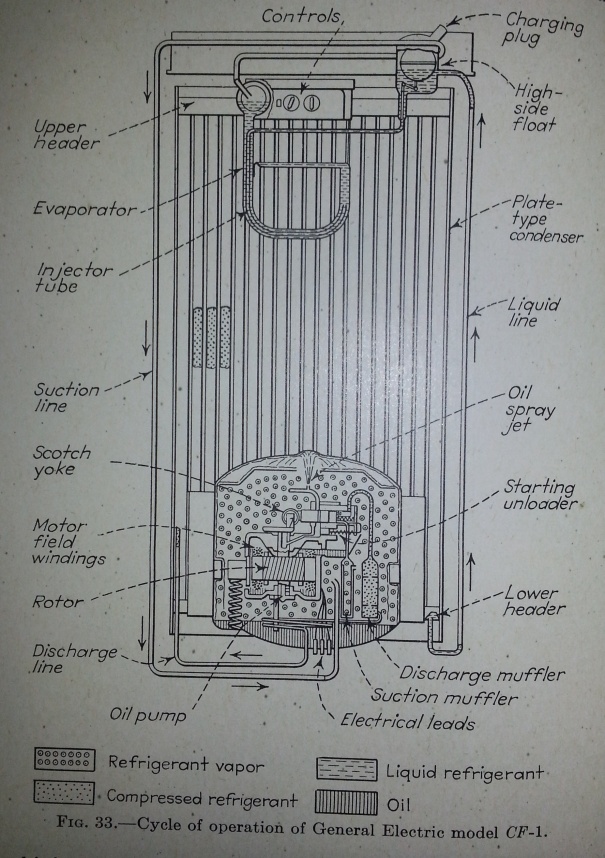

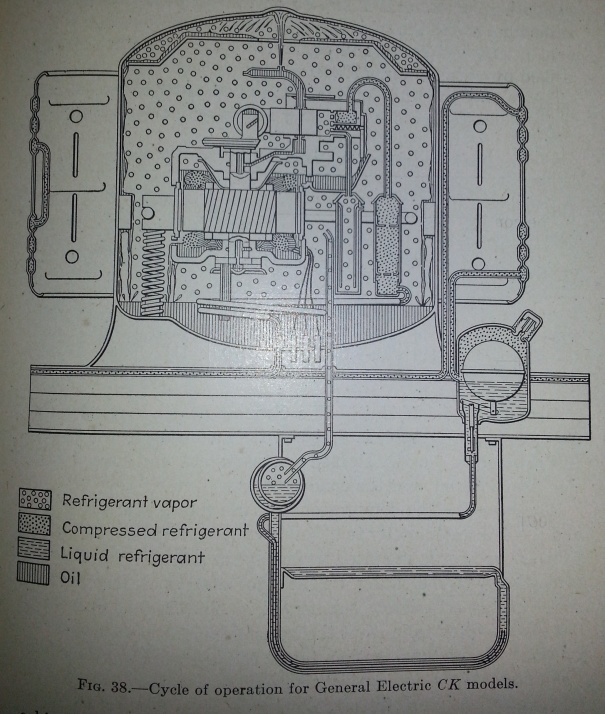

A GE Monitor Top style refrigerating unit. A hermetic system with what looks like a rotary compressor and oil pump lubricating pump. The condensers were passively cooled by convection and the refrigerant control was of the High Side Float type. A small chamber, similar to a liquid receiver, was partially embedded in the cabinet top and fed by the condenser coil. When the liquid refrigerant collected to a certain level, a float would rise, opening a valve to admit refrigerant to the evaporator. The evaporators were the gravity flooded type. The pressured refrigerant was introduced towards the bottom of the coil in a manner to encourage liquid flow. The suction tube was somewhat protected by a baffle and some sort of oil collecting cup or basin.

Another GE system. This one, with the compressor built underneath the cabinet and a steel plate condenser with stand offs for cooling on the back. Again, a high side float.

Another GE system. This one, with the compressor built underneath the cabinet and a steel plate condenser with stand offs for cooling on the back. Again, a high side float.

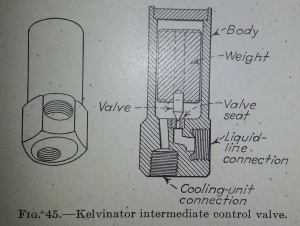

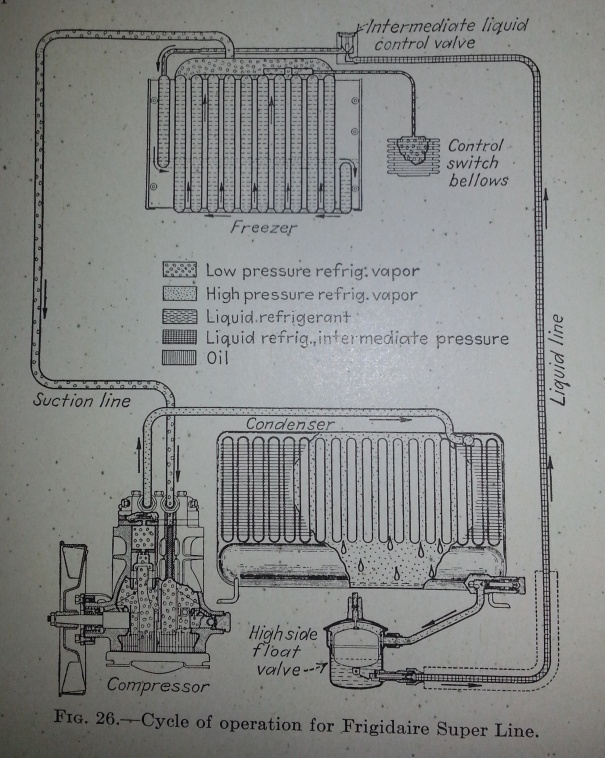

Some high side floats were designed to be near the condenser below the cabinet like this Frigidaire. The problem found in these systems was that the outlet of the float valve is at suction pressure, leading to frosting before the refrigerant is admitted to the evaporator coil within the cabinet. The solution to this was something called an Intermediate Pressure Control Valve. This valve required a certain minimum pressure in the line from the float valve, keeping pressure enough to prevent phase change.

A simple, yet effective solution by Kelvinator uses a weighted mass to control refrigerant flow.

A simple, yet effective solution by Kelvinator uses a weighted mass to control refrigerant flow.

And finally, a Frigidaire refrigerator with capillary tube type refrigerant control and a dimpled steel plate back wall condenser. An all hermetic, cheap, example of refrigerator designs of years to come.

M.C. Pletcher

So I have a rebuilt 1930 Fridgidaire W18 with its original evaporator and low side float still intact but rendered obsolete by a new capillary based system which wraps the original evaporator. The original remote compressor was disposed of in favor of a modern custom build which fits under the cabinet. Having been fumigated by SO2 during the removal I can testify to its potency. The rebuilt machine is the best refridgerator I have ever owned.

That’s great Curt! I would love to own a piece like that. It only i had the room. Personally, I would prefer to leave the original system intact, especially if it were operational. However, to use the thing, one would have to retrofit it with a quieter and safer vapor compression system as you did. Do you have any pictures of it online anywhere?

Curt, would you ever be interested in selling the Frigidaire w-18?

The GE unit shown is a scotch yoke type, not rotary. The first picture is of a CK monitor top machine while the other I think is a CF flat top refrigerator. We have a lot of information on these machines as well as other antique refrigerators at our forum : http://monitortop.freeforums.net/

Curt, would you ever be interested in selling the Frigidaire w-18?

Im helping out a friend of mine. He was trying to find out what the value is on what we believe is a 1920-30 williams ice o matic fridge. This thing is heavy!! Dont believe its in working order. Would u be able to help find its value?

I can try to send u some

Pics of it.

Yeah. Please do. I’m not a collector, but if I had the room, I would. I’d be happy to take a look. praxis15501@yahoo.com

Hello LB

Does you friend still have the ice o matic fridge, my son has one and it needs some parts. His is runninf but the door latches are worn out. Might be interested in buying a spare for parts. Were are you located.

Don

[…] in refrigerators is no secret. There are a large number of posts on this blog pertaining to antique refrigerators, and perhaps as many about my own thoughts on refrigerators. It would seem that I may have a new […]

Thank you for hosting such an interesting subject. I have a small collection, including a ca 1917 Pefection absorption unit and a very old oak reach in box from a butcher shop. Unfortunately, I have no idea what the original refrigeration system was or looked like, and researching this sort of thing on the internet is all but impossible… Suggestions? Thanks, Paul

Hey Paul, thanks for the comment. Sorry I have been absent for a while. The Superfex is by far one of my favorite models! I have poured over every patent i could find from the company, and even have the materials to construct my own. They are rather rare, I believe. I only know of two or three in existence. Here is a patent from 1927, but there are several more with varying levels of complexity. https://patents.google.com/patent/US1816975A/en?q=intermittent+absorption&assignee=perfection&before=priority:19280101

I’d be happy to talk to you about it sometime, if you like. Love to see some pictures!

Can you shed any light on whole building refrigeration systems where say, all units in an apartment building share the same refrigeration system for all fridges in each unit?

I’m doing a kitchen remodel and from what I can tell, the fridge built into the cabinetry appears to be a Frigidaire judging by the shelf supports and door seal style. Anyway. There is no compressor. The chiller unit that would hang from the top is missing as is the original door, but there are two copper tubes that go into the wall of the building and there is a distribution network for each fridge in the building. This building is in San Francisco and was built in the 30’s.

[…] Read More […]

I have a 1932 leonard refrigerator. Not being a purist I’m changing it over to a cap tube system .The compressor is out of a mini fridge and I’m building a condenser for it.

Peter Scott, p.m.scott@reading.ac.uk

Hello, may I introduce myself as Peter Scott, a lecturer at the University of Reading, Great Britain. I I found your blog on 1930s home refrigerators very useful for an article I am working on, looking at the U.S. refrigerator industry during the 1920s and 1930s. I would be very grateful if you might be able to let me reproduce the photo of the cycle of operation for the Frigidaire Super Line, so I can show the readers what a 1930s home refrigerator mechanism looked like. I would be very happy to send you a copy of article, when it is finished.

Thanks and best wishes,

Peter